We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

PERFORMANCE SPECIFICATIONS

Reference temperature 70°F (21°C)

Accuracy, Three Classes (% Span): ±.25 ±0.5 ±1.0

Includes non-linearity (Terminal Point Method), hysteresis,

non-repeatability, zero offset and span setting errors

Best Fit Straight Line* (BFSL): ±.20 ±.40 ±.50

Includes non-linearity hysteresis, non-repeatability errors

*Add ±.05% for ranges above 5000 psi

Stability:

±0.25% Span/year @ reference conditions

Durability: Greater than 10 million cycles

ENVIRONMENTAL SPECIFICATIONS

Temperature Limits:

Storage: –40 to +125°C (–40 to 257°F)

Process: –40 to +125°C (–40 to 257°F)

Operating: –40 to +125°C (–40 to 257°F)

Compensated*:–20 to +85°C ( –4 to 185°F)

*Consult factory for other options

Temperature Effects: –20 to +85°C (–4 to 185°F)

• 1.0% of Span for .25% Accuracy Class

• 2.0% of Span for .50% and 1.0% Accuracy Classes

Humidity Effects: No performance effects from

0 to 95% relative humidity, non-condensing,

0-100% RH with “W” enclosure.

*Consult factory

FUNCTIONAL SPECIFICATIONS

Respone Time: <2ms

Pressure Ranges: Vacuum, gauge, compound and absolute

pressure from 0-5 psi through 0-10,000. Equivalent ranges

in bar available. See order guide section (reverse.)

Vibration Effect:

Shock: 100g Peak, 11ms

Random: 10g RMS, 20-2000Hz

Sweep: 50-2000Hz, 5g peak

Position Effect: ± 0.02% Typical

CE Mark (standard): EN 61326:1997 + A1: 1998 Annex A

Heavy Industrial Immunity (Annex A, Table A.1)

Light Industrial/Residential Emission (Table 4)

Overpressure (F.S.)*: Proof Burst

0#/vac. to 300 psi 1.5 x F.S. min. 2 x F.S.

500-10,000 psi 1.2 x F.S. 1.5 x F.S.

*For higher overpressure ratings use XK8 option.

ELECTRICAL SPECIFICATIONS

Output Signal: Supply Voltage: (unregulated)

Minimum Maximum

0-5Vdc (3 Wire) 12Vdc 36Vdc

0-10Vdc (3 Wire) 14Vdc 36Vdc

1-5Vdc (3 Wire) 10Vdc 36Vdc

1-6Vdc (3 Wire) 10Vdc 36Vdc

4-20mA (2 Wire) 12Vdc 36Vdc

0.5-4.5 (3 Wire) 4.5Vdc 5.5Vdc

Ratio-metric

Power Requirements:

Supply Current: <5mA for voltage outputs

Electrical Terminations: See To Order section (reverse)

for options

Circuit Protection: Reverse polarity and mis-wire protected

Insulation Resistance (Circuit to Case): 100Mohm @ 30Vdc

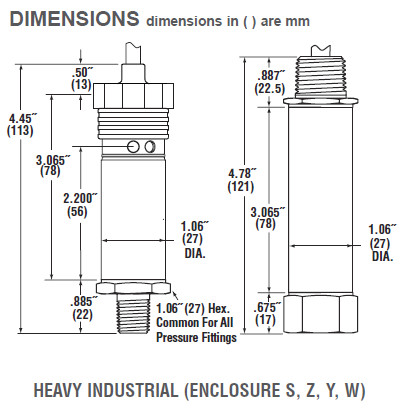

PHYSICAL SPECIFICATIONS

Case: Material 304SS

Wetted Materials: 316L SS diaphragm and pressure port,

optional 17-4PH SS diaphragm and 316L SS pressure port

(see How to Order Section).

Ingress Protection Rating:

Enclosure Code Rating

Basic (S) IP65, NEMA 4X

Zero/Span (Z) IP65, NEMA 4X

All Welded (w/Z/S) (Y) IP65, NEMA 4X

All Welded (w/o Z/S) (W) IP67, NEMA 6

- • Test stands

- • Compressor control

- • Hydraulic systems

- • Process automation

- • Pump

- • Pneumatic systems control